Generation 3 Pumpkit

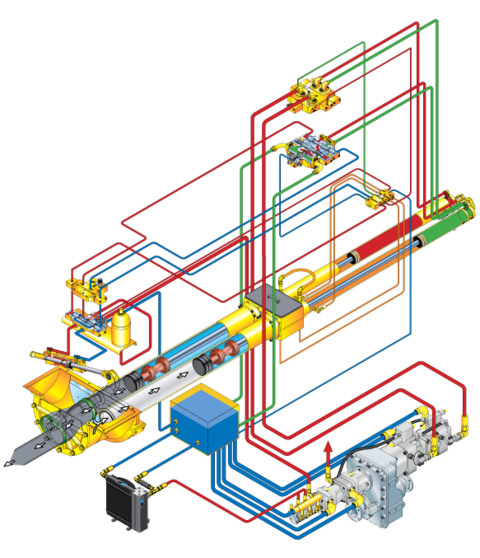

Proper cooling of the hydraulic oil is critical to continuous operation under demanding conditions. In addition, filtration is the single most important method of keeping the hydraulic system operational. That’s why the Schwing G3 design continuously draws hydraulic oil from the tank and circulates it through the filter and high efficiency cooler. Even when the concrete pump is not engaged, this separate hydraulic circuit continues to operate for protection and performance.

Redesigned for 800 LPM of oil, the 3 High Flow Control Block is the brain for the all hydraulic system. The block incorporates the Soft Switch into the relief valve and the accumulator manifold into the S3 spool valve for a compact, simpler design. Multi Port Shifting is an important part of the twin circuit system, which uses accumulator pressure to switch the S3 valve. Faster switching of the S3 translates to smoother pumping. The S3 block and system accumulator are separated from the control block and located near the hopper for easy access.

The material cylinders contain rubber rams that are connected to the differential cylinder rods. One side will push the concrete through the Rock Valve™ while the opposite side will draw concrete from the hopper. Now available with up to 10 inch (250mm) diameter and 98-inch (2500mm) stroke length, G3 pumpkits deliver 30% more concrete with every stroke than competitive brands. Fewer strokes translate to smoother pumping, less wear and longer boom life.

The hydraulic pumps for the concrete pump circuit are bent axis, variable displacement, piston pumps. They are horsepower controlled, which means that as pressure rises towards maximum, the flow can decrease, so the power consumption remains constant. This pump assures that the truck engine will not bog down under difficult pumping conditions. The pump also accepts external signals from the hydraulic stroke limiter for control of the output.